AC Axial Fan Design Comparison for Industrial Cooling: Important Features and Applications

AC axial fans are indispensable for industrial cooling because they serve a critical purpose in applications needing high-volume airflow over the equipment, enclosures, and HVAC units. These fans are quite popular owing to their uncomplicated design, extended lifespan, and ability to interface with legacy power systems. For AC fan B2B customers—engineers and facility administrators—the understanding of differences in AC axial fan designs relative to performance aids in improving cooling system efficiency while managing costs.

The article looks at the design details, distinct features, and typical applications of AC axial fans with a particular focus on searching for a wholesale electric cooling fan for several industrial applications.

Fundamentals of AC Axial Fan Design

AC axial fans derive their name from airflow direction, which is parallel to the fan shaft, thus making axials best suited for applications where high airflow and low pressure are essential. These fans vary in size, number and type of blades, materials used, and type of motor employed; each distinct from the others, impacts performance factors like airflow and noise levels, and energy efficiency.

The most important aspects of an AC axial fan design focuses on:

- Blade Geometry: Responsible for the airflow efficiency and the level of noise emitted. Curved blades tend to operate more quietly compared to flat blades that usually yield static pressure.

- Frame Material: Most common is aluminum, steel, and plastic which determine the weight of the fan and its resistance to corrosion, and durability.

- Motor Type: Common motors are shaded pole and capacitor-start, which greatly differ in efficiency and start torque.

- Mounting Options: There are a variety of panel mount, duct mount, and free-standing configurations based on intended purpose.

These design features alone affect how suitable the fan would be for use in industrial settings like manufacturing floors, data centers, or HVAC systems.

AC Axial Fans Industrial Advantages

AC axial fans provide a range of features that ensure its continued use for industrial cooling purposes:

- Reliability: AC fans have a long operational life and some require back up so they’re well suited to be relied on.

- Affordability: AC axial fans have a lower purchase price compared to both DC and EC fans, the added benefit is simple installations which integrate nicely with existing AC frameworks.

- Workload Reduction: Their durable build ensures minimum effort is needed when maintenance is required, especially with the presence of filters or grills designed to prevent dust blockage.

- Scalability: Their availability in multiple sizes and airflow ratings makes them suitable for a range of industrial requirements.

For widespread use within facilities, having a reliable wholesale electric cooling fan ensures better pricing for bulk orders, along with guaranteed quality.

See Also: The Influence of Tech on Modern Communication

Different Applications Across Industrial Settings

AC axial fans serve different industries for specific operational requirements. Let us investigate some common examples.

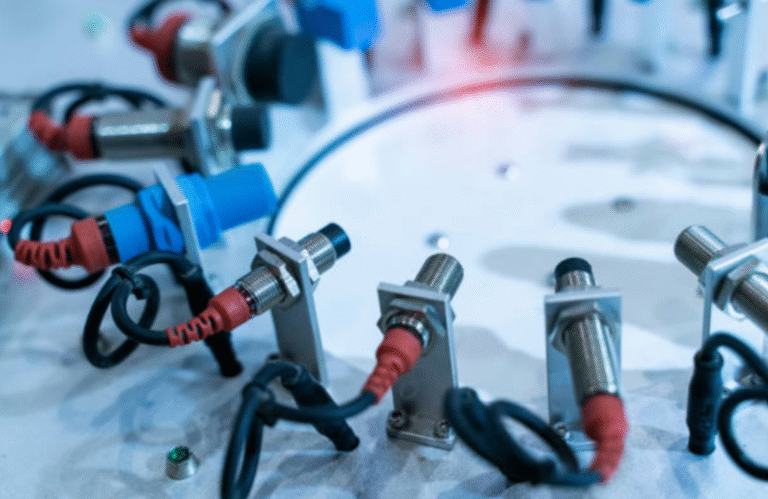

Electronics Cooling

In the thermal management of electronics, enclosures frequently utilize axial fans to remove the heat emitted by power supplies, processors, and transformers. These fans are typically installed onto panels or cabinets — and in this case, must be capable of operating quietly while providing constant airflow.

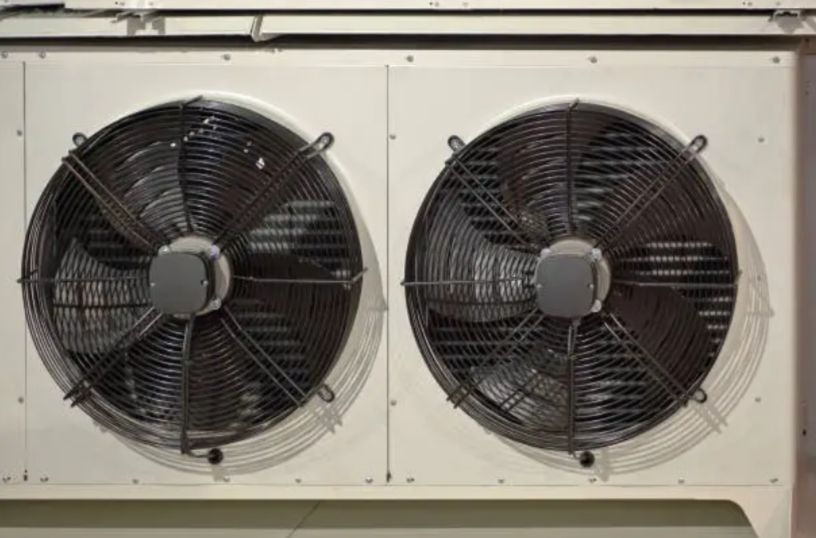

HVAC Systems

In the heating, ventilation, and air conditioning of a space, AC axial fans serve to propel large amounts of air through various parts such as ducts, evaporators, and condensers. Their ability to provide adequate airflow with a constant power supply means they are well suited for HVAC applications in commercial buildings and factories.

Server Racks and Data Centers

Even though EC fans are becoming more popular in data centers, many smaller server rooms and network closets still use AC axial fans as they are more straightforward and cost-effective. These fans are critical for equipment cooling to ensure operational availability and prevent overheating.

Refrigeration Units

Condensers and evaporators of refrigeration systems prominently feature axial fans. They are critical components because of their small form factor, high airflow rate, and capability to maintain stable internal temperatures in refrigeration storage, refrigerated display cases, and cooling transport vehicles.

Industrial Cabinets and Enclosures

Another common use is enclosure and panel cooling. Provided the IP ratings are adequate, the fans can be employed in harsher conditions to control the hot air stagnation inside control boxes and automation systems.

An ac axial fan manufacturer and wholesale electric cooling fan products can tailor to each of these markets and optimize fan parameters such as size, airflow requirements, operational constraints, and other factors to ensure maximized efficiency.

Factors to Consider When Choosing an AC Axial Fan

Cooling efficiency and operational performance of the fan selected are reliant on several aspects. B2B buyers, for example, must analyze the following:

- Airflow Rating (CFM): Output in cubic feet per minute should match the scale of the space or equipment for optimal Airflow.

- Static Pressure: Determine if the fan will be in a blowing or sucking position in respect to the filters or ducting, which can add additional resistance.

- Voltage Compatibility: AC fans come in standard voltages of 110V, 220V, etc, so pick the one that corresponds with your system voltage.

- Symbol of Ingress Protection (IP Rating): Industrial fans are used in dusty or moist environments hence it is advised to select equipment with high IP ratings.

- Level of Noise: With the presence of noise indoors or noise sensitive areas, quieter fan models might be preferred.

- Capacity of bearings: Affecting noise and life span of a fan, these bearings come in sleeve or ball forms. In high-load settings, ball bearings are more durable, therefore tend to outlast longer.

Adopting the service of a skilled axial fan manufacturer and wholesale electric cooling fan distributor would achieve the recommended regulatory compliances as well as the relevant operational criteria.

The Function of Bulk Purchasing in Cost and Quality Management

For industrial applications with centralized cooling for several machines or several locations, ordering fans in advance will control the cost while assuring quality and ease of inventory management on a per unit basis. Long-term contracts with a supplier generally results in:

- Better Customization: Designed fans also undergo modifications for plug type, mounted wires, skirt length, and other obstacles. For bulk purchases, customization is effortless.

- Known Lead Times: Timetable based deliveries minimize downtime and save sourcing effort on short notice.

- Technical Maintenance: Trouble post-warranty maintenance is easy with direct contacts to the manufacturers or wholesale partners and better planned maintenance schedules.

Checking whether the selected partner for a wholesale electric cooling fan fulfills international norms pertaining general safety and operational efficiency is crucial for reliability in operations over time.

Conclusion

For the vast cooling requirements of industrial cooling systems, AC axial fans provide a practical solution while remaining durable and cost effective. They are widely used in manufacturing, HVAC, IT, and refrigeration due to their simple designs, ability to integrate with pre existing systems and infrastructures, and ease of scaling. With more integrated control of cooling functionalities, energy efficiency, and lowered maintenance costs, businesses can take advantage by teaming up with an ac axial fan manufacturer and wholesale electric cooling fan distributor.

Smart procurement and selection of fans becomes indispensable as the workload and cooling requirements increase, particularly in high density and high performance settings. Sourced properly, AC axial fans still remain cornerstone technology geared for dependability and value.