Top Proximity Sensor Brands for Industrial Automation: What Sets Them Apart?

Proximity sensors are increasingly becoming a part of industrial automation due to their accuracy, safety features, and helping streamline processes. The sensors are expanding their roles because factories are transforming into smart factories and are becoming more and more digitized. For strategic decision makers like procurement managers, system integrators, and engineering managers, selecting the right proximity sensor brands poses a critical challenge as it impacts system efficiency, maintenance intervals, and productivity.

With such a wide variety of sensor types and technologies, what brand does stand out for B2B professionals? The answer is brand reputation, flexibility, reliability, validity, and, of course, the strength of the dealership in the field of automation parts allied with your operational and organizational needs.

Let’s identify the brand best performers in regards to proximity sensors so that industrial buyers have more options and choices while sourcing these essential parts.

The Importance of Proximity Sensors in the Current Industry

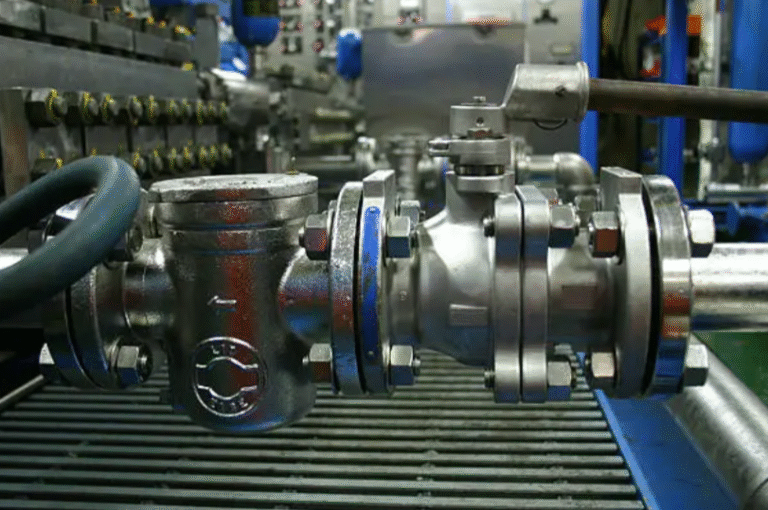

Their utility can be seen in several automation features as proximity sensors are used widely. These sensors use electromagnetism, capacitance, or even light to determine whether an object is in a given area without making physical contact. Since they do not come in contact with the object, they are suitable for high-speed, high-volume tasks within industries because they do not wear down as quickly as contact sensors do.

Some industries that make use of proximity sensors include the:

- Automotive (safety controls, automation on the assembly lines)

- Food and Beverage (engaged in non-contaminated packaging, non-contact operations)

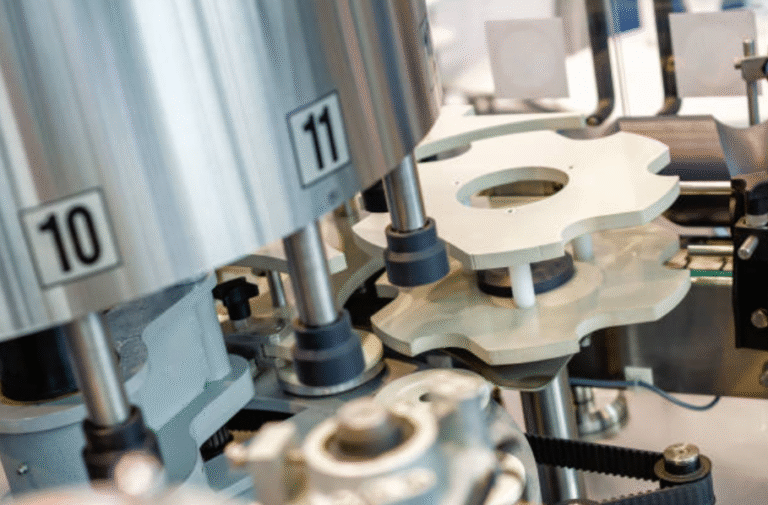

- Pharmaceuticals (fill the materials precisely, detect materials)

- Electronics (place the components during PBC production)

- Logistics and warehousing (navigate robots, detect packages)

High end proximity sensor brands are designed to survive harsh oils, moisture, vibrations, and even changing temperatures. Moreover, their uptime and safety relies heavily on these sensors.

See also: Can the Right Mattress Help With Chronic Pain Conditions?

What Top Brands of Proximity Sensors Do Differently?

Buying the sensor is a one time investment but it will impact the efficiency as well as the dependability of the system long term. Here’s what sets the top brands of sensors from the rest.

Superb Detection Precision and Accuracy

Top brands put a high premium on accuracy. As with an inductive sensor tuned for metal detection or a capacitive sensor for plastic and level liquid sensing, leading brands offer finely tuned ranges of detection and signal drift. This optimizes performance and reduces false triggers, which is particularly important in sophisticated automated systems.

In addition, high-quality brands offer increased ranges of sensing distances and object materials, allowing greater freedom in design to engineers.

More Sophisticated Sensing Methods

With the 4th revolution of industry underway, manufacturers of proximity sensors are adding smart features like:

- IO-Link support for real-time diagnostics and changing parameters

- Automatic adjustments for set and externally monitored changes self-calibration

- All-in-one sensors digital, analog, and multi-signal output

These capabilities ensure that the sensors not only provide presence detection, but voice critical system health information—adding logic to your automation system.

B2B buyers stand to gain a competitive edge in system design and reliability if they choose to work with an automation parts dealer who stocks such advanced models.

Environmental Protection and Reliability Factors

It is uncommon for an industrial environment to be deemed as ideal. Issues such as dust, oil, moisture, vibration, and electromagnetic interference are all very common. Leading proximity sensor suppliers put money into ruggedized designs with:

- High IP rating

- Stainless steel or chemically resistant outer covers

- EMI/RFI shielded wiring

Sensors constructed from more rugged materials allow less maintenance, fewer equipment failures, greater safety, and improved safety in other areas.

Certifications and Compliance

Sensors made by reputable brands comply with legal international standards. Compliance certifications guarantee proper safety, interchangeability, and quality control. These include, but are not limited to:

- ISO 9001/14001

- CE and RoHS compliant

- Relevant ATEX certification for potential explosive environments, FDA for food contact

While such compliance may seem to cause issues, such measures actually solve a lot of possible recalls, lawsuits, and integration problems.

If you require more information regarding such standards, a qualified automated systems parts dealer may prove helpful by providing the correct, across the certification and compliance, products for your industry.

Customization and Special Applications

No two applications are alike: some may include the challenge of fitting into tight spaces or withstanding extreme heat, while others may require the ability to detect non-metallic materials. Custom features are offered by most top brands, such as:

- Sensing elements with non-standard target detection ranges: Specialized miniature or ultra-flat sensor designs catered to specific applications.

- Compact systems like built-in amplifiers or controllers.

This level of customization is crucial with OEM or other forms of specialized manufacturing. As an example, any reputable automation parts dealer will have the ability to provide off-the-shelf customization, or work to create tailor-made sensor solutions.

Support and After-Sales Service

After-sales support services provided by leading brands extend to:

- Guides for installation together with 3D CAD Models.

- Consulting alongside providing technical support and issue troubleshooting.

- Warranty services with flexible terms together with quick replacements.

In addition to everything mentioned above, sensor availability is another critical issue. Disruptions in delivery of parts may result in halting production lines. This is why having a trusted automation parts dealer with real-time inventory access and quick delivery is essential for automated workflows.

Why Importance Of Your Automation Parts Dealer Has Increased

Selecting a reputable automation parts dealer requires just as much attention and care as choosing the right sensor brand, given the intricacy of global supply chains and the constant change of lead times. With an automation parts dealer, you are offered easy access to advanced technologies, automation stock levels, and professional advisory services.

For a properly trained automation parts dealer, those in need should expect to receive the following:

- A well-stocked catalog of reputable brands for proximity sensors,

- Part substitution guides featuring older parts,

- Comprehensive engineering for application tailored systems,

- International transport and legal consultant services.

Proximity sensors both from the sensor brands mentioned before as well as an experienced automation parts dealer provide operational efficiency and enhance the reliability of purchase across the system.

Conclusion

In conclusion, precision, resistance to wear and tear, flexibility, alongside sophisticated attributes, embody the best brands for installation proximity sensors which are critical for highly automated manufacturing systems. However, these attributes don’t change the fact that the brand still isn’t enough without a qualified automation parts dealer. Qualifications greatly help maximize the advantages of high-performance sensors due to assured selection and servicing of products.

An ideal combination of sensor technology and distribution expertise enable the business to leverage smart automated systems, greater uptime, and amplified success in scalable automation.